Transforming Automation with Advanced Autonomous Mobile Robots (AMRs)

2025-01-16

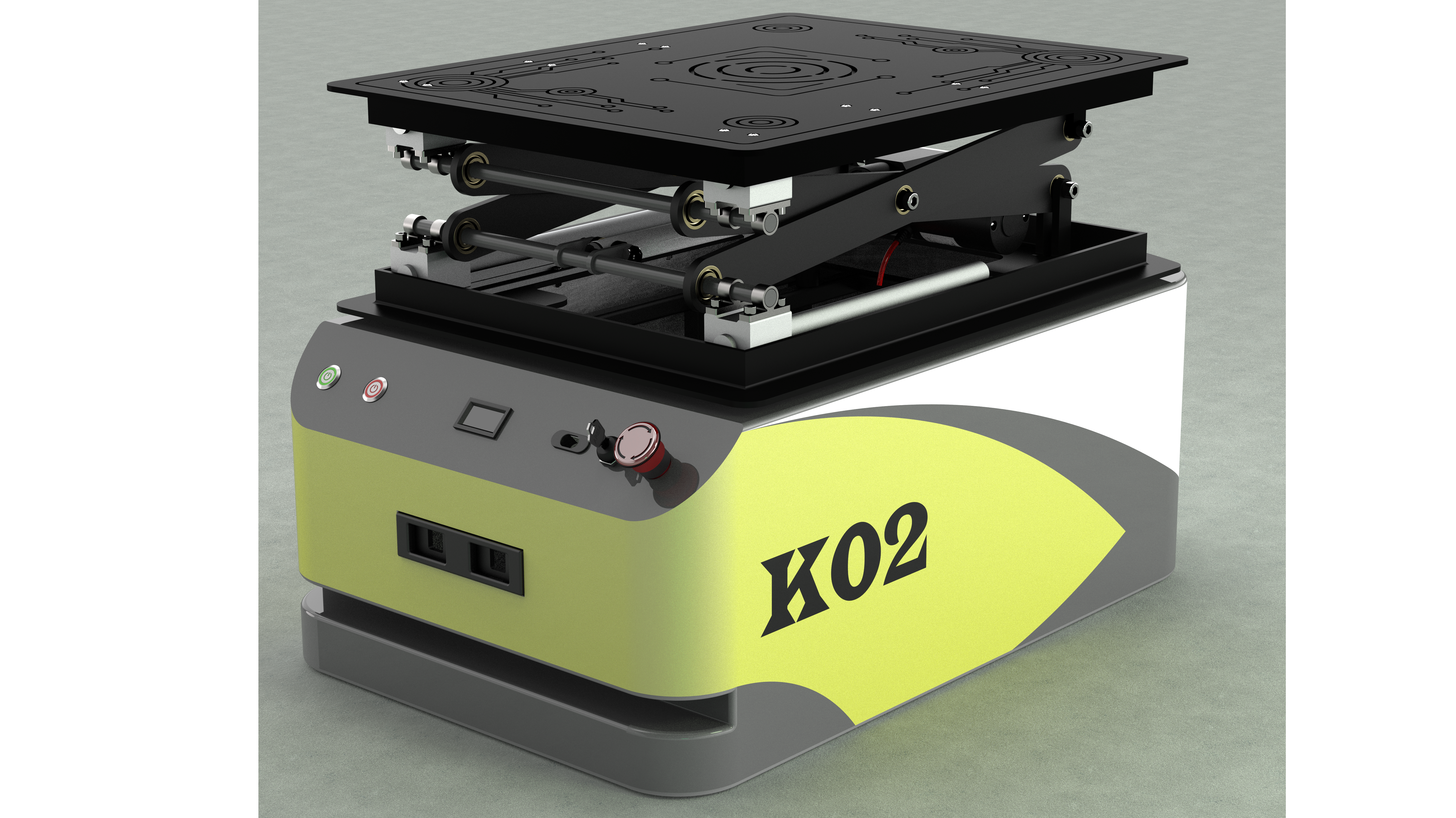

In the digital age, automation has become indispensable for organizations aiming to enhance operational efficiency and gain a competitive edge. One of the most impactful innovations reshaping the future of automation is Autonomous Mobile Robots (AMRs). These self-driving robots are revolutionizing industries by improving productivity, reducing operational costs, and boosting safety. Their ability to seamlessly integrate into diverse industrial applications is transforming how businesses approach their automation strategies.

What Are Autonomous Mobile Robots (AMRs)?

Autonomous Mobile Robots (AMRs) are intelligent, self-guided robots designed for material handling, transportation, and various other tasks within dynamic, often unstructured environments. Unlike traditional Automated Guided Vehicles (AGVs), which follow fixed paths or predefined routes, AMRs use advanced AI-powered navigation systems, LiDAR, vision sensors, and machine learning algorithms to autonomously navigate complex environments. Their ability to adapt to changes in their surroundings, detect obstacles, and make real-time decisions makes AMRs a game-changer in industrial automation.

Key Benefits of Autonomous Mobile Robots (AMRs) in Automation

Enhanced Operational Efficiency

One of the key drivers behind the adoption of AMRs is their ability to significantly increase operational efficiency. AMRs automate material transport tasks within warehouses, manufacturing plants, and distribution centers, ensuring continuous operation and reducing downtime. Their ability to work 24/7 without breaks leads to faster cycle times, higher throughput, and streamlined workflows, making them indispensable in industries like logistics and supply chain management.

Cost Reduction and Return on Investment (ROI)

While the initial investment in Autonomous Mobile Robots (AMRs) may appear high, the long-term cost savings are substantial. AMRs reduce labor costs by automating repetitive tasks that would otherwise require significant human resources. They also help reduce energy consumption, as their energy-efficient design ensures lower operational costs over time. The ability to operate continuously with minimal human intervention results in a higher return on investment (ROI) as businesses realize cost reductions in workforce management, logistics, and inventory handling.

Improved Safety and Risk Mitigation

Workplace safety is a critical concern in industries involving heavy machinery or hazardous environments. AMRs play a vital role in enhancing safety by automating tasks that would typically expose workers to potential risks. With AI-based navigation, collision avoidance systems, and real-time sensors, AMRs can safely navigate and avoid obstacles, reducing the likelihood of workplace accidents. This not only improves safety but also ensures compliance with health and safety regulations across various industries.

Scalability and Flexibility

AMRs offer unparalleled scalability and flexibility, making them ideal for businesses with evolving needs. Unlike traditional automation systems that may require significant infrastructure changes, AMRs can be easily deployed and integrated into existing workflows. Their adaptive software allows businesses to reprogram or upgrade AMRs to meet changing demands or add new tasks without extensive downtime, providing a highly flexible automation solution.

Seamless Integration with Other Technologies

The ability of AMRs to integrate with other industrial technologies, such as Warehouse Management Systems (WMS), Enterprise Resource Planning (ERP) platforms, and Internet of Things (IoT) devices, is another major advantage. This integration creates a more cohesive, automated ecosystem, where data from AMRs can be collected, analyzed, and used to optimize supply chain management, inventory control, and production scheduling. By connecting AMRs with existing technologies, businesses can unlock new levels of operational insight and efficiency.

Applications of AMRs Across Industries

The versatility of AMRs makes them suitable for a wide range of industries, including:

Warehousing and Distribution: AMRs are widely used in warehouse automation to transport goods between different areas, manage inventory, and speed up order fulfillment. Their ability to navigate complex layouts and avoid obstacles ensures a smoother, more efficient workflow.

Manufacturing: In manufacturing environments, AMRs help automate the delivery of materials to production lines, reducing delays and improving overall production efficiency. They also assist in transporting finished products to storage or shipping areas, ensuring that products are always available when needed.

Healthcare: AMRs are increasingly being used in hospitals and healthcare facilities to deliver medications, medical supplies, and documents between departments. This automation improves the efficiency of healthcare operations while ensuring the safe and timely delivery of critical supplies.

Retail: In retail environments, AMRs can assist with inventory management, shelf restocking, and logistics, ensuring that products are readily available for customers and improving the overall customer experience.

Overcoming Challenges and Future Outlook

While the benefits of AMRs are clear, there are challenges that businesses must address when adopting this technology. Issues related to cybersecurity, AI reliability, and integration with legacy systems can create obstacles in the initial stages of deployment. However, advancements in robotics, AI, and machine learning are continuously improving the capabilities of AMRs, making them more reliable, affordable, and secure for industrial applications.

Looking to the future, the role of AMRs in industrial automation will continue to expand as technology evolves. With further improvements in artificial intelligence (AI), machine learning, and robotic systems, AMRs will become even more capable of handling complex tasks, offering greater flexibility, and driving more significant efficiency gains across industries.

Conclusion

Autonomous Mobile Robots (AMRs) are transforming the landscape of automation, providing businesses with powerful, flexible, and cost-effective solutions to increase productivity, improve safety, and reduce costs. Whether in warehousing, manufacturing, or healthcare, AMRs are enabling businesses to optimize their operations and stay competitive in a rapidly changing market.

For companies looking to harness the full potential of AMRs, Niha Robotics offers cutting-edge solutions tailored to meet your specific operational requirements. With expert guidance and state-of-the-art AMR technology, Niha Robotics is committed to helping your business achieve new heights of efficiency, safety, and profitability through advanced autonomous mobile robots.