Maximizing Operational Efficiency with Automated Guided Vehicles (AGVs)

2025-01-22

In the modern world of logistics, manufacturing, and material handling, businesses strive to improve efficiency, reduce operational costs, and enhance safety. One technology gaining significant traction for meeting these challenges is Automated Guided Vehicles (AGVs). These intelligent, self-driving vehicles are revolutionizing industries by streamlining the movement of materials and goods, ultimately boosting productivity and minimizing human error. AGVs are becoming indispensable tools in various sectors, including warehousing, manufacturing, e-commerce, and automotive industries.

What Are Automated Guided Vehicles (AGVs)?

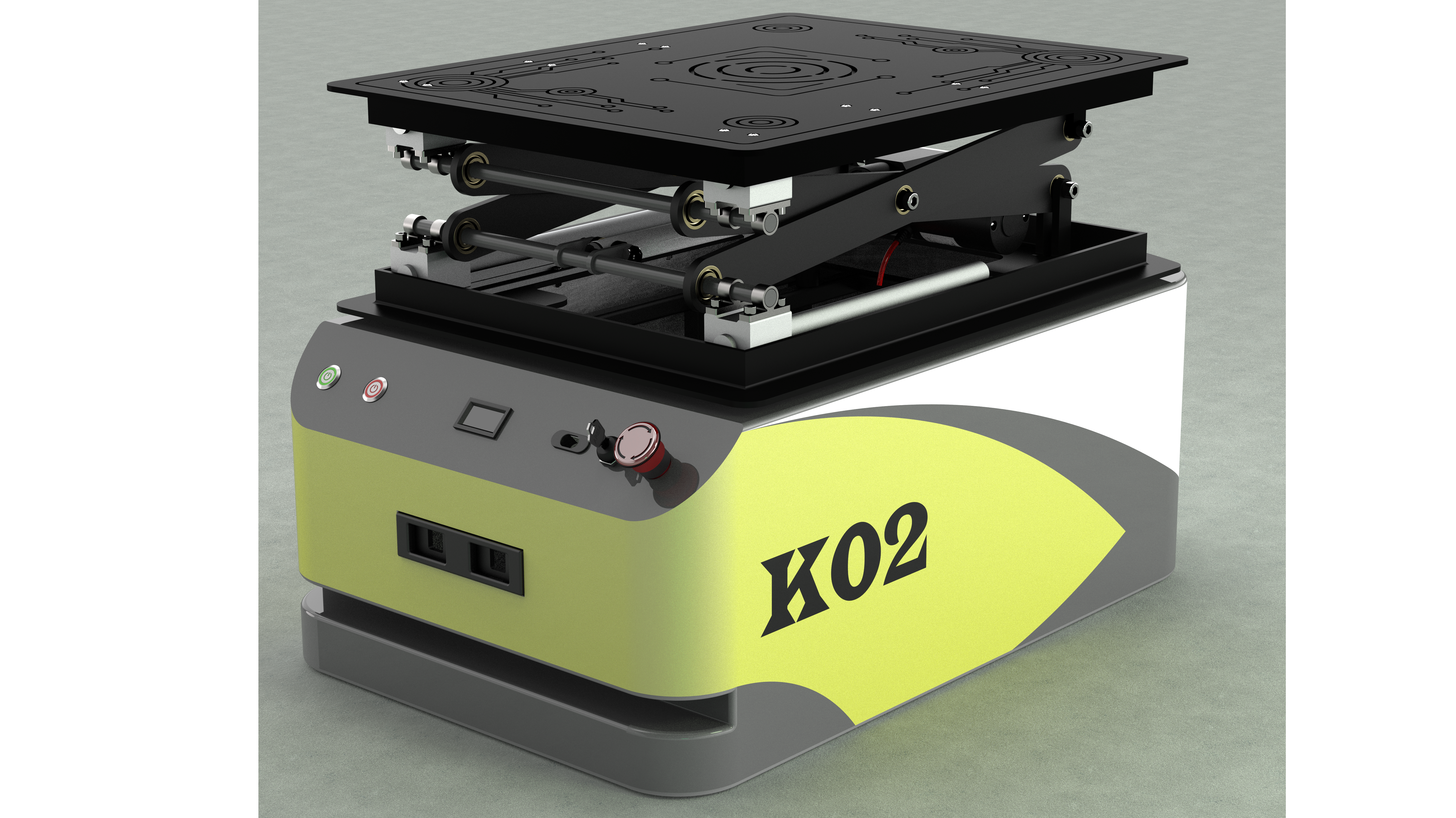

Automated Guided Vehicles (AGVs) are robotic vehicles equipped with navigation systems, sensors, and cameras that enable them to follow predetermined paths and autonomously transport materials and goods across a facility. These vehicles can be programmed to carry loads, move between different areas, and perform tasks like pallet transportation, order picking, and even inventory management. The AGV systems are capable of operating continuously, which enhances the overall speed and productivity of operations.

Key Features of AGVs

Autonomous Navigation: AGVs are equipped with advanced navigation technologies such as laser guidance, magnetic strips, and vision-based systems that enable them to move independently without human intervention.

Safety Features: Safety is a critical aspect of AGVs. These systems include collision detection, emergency stop buttons, and safety sensors that ensure safe operations in busy environments.

Scalability: AGV systems are highly scalable, making it easier for businesses to expand their automated operations as demand grows.

Energy Efficiency: Most modern AGVs are designed to be energy-efficient, equipped with long-lasting batteries that can operate for several hours before needing a recharge.

Types of Automated Guided Vehicles (AGVs)

Unit Load AGVs: These vehicles are primarily used to transport large, standardized loads such as pallets, crates, and boxes. They are commonly found in warehouses, distribution centers, and manufacturing plants.

Towing AGVs: Towing AGVs are used to tow carts or trailers loaded with goods or materials. They are typically employed in automotive manufacturing and heavy industries.

Forklift AGVs: These AGVs are designed with forks to lift and move materials vertically. They are ideal for stacking and inventory management in warehouses and storage facilities.

Automated Mobile Robots (AMRs): Unlike traditional AGVs, AMRs use advanced AI-powered navigation systems, allowing them to navigate more dynamically and adapt to changes in the environment.

Benefits of Automated Guided Vehicles (AGVs)

Increased Efficiency: AGVs operate continuously without breaks, ensuring that tasks such as material transportation and order fulfillment are carried out quickly and efficiently. This leads to shorter cycle times and improved throughput.

Cost Savings: By automating material handling and reducing the need for manual labor, AGVs help businesses cut down on operational costs and improve their return on investment (ROI).

Enhanced Safety: AGVs are designed to work in environments with minimal human interaction, reducing the risk of workplace accidents, injuries, or material damages.

Flexibility: AGV systems can be easily adapted to suit various industries, from logistics and pharmaceuticals to automotive manufacturing and food processing.

Real-Time Monitoring: Modern AGV systems are connected to warehouse management systems (WMS) and enterprise resource planning (ERP) software, enabling real-time tracking of materials, vehicle status, and performance metrics.

Applications of Automated Guided Vehicles (AGVs)

Manufacturing: AGVs are widely used in automotive manufacturing to move parts and components between assembly lines, improving production efficiency and minimizing downtime.

Warehousing and Distribution: In e-commerce and logistics, AGVs help streamline processes such as order picking, inventory management, and material handling, ensuring faster fulfillment times and better customer service.

Pharmaceuticals and Healthcare: AGVs are essential in pharmaceutical manufacturing and hospital material transport, ensuring that sensitive materials are handled with care and precision.

Food Processing: In the food industry, AGVs are used to transport raw materials, finished products, and packaging, maintaining hygiene and speeding up production processes.

Why Choose The Team Robotics for Your AGV Solutions?

For businesses looking to revolutionize their material handling processes, The Team Robotics offers expert solutions in Automated Guided Vehicle (AGV) systems. With a proven track record in AGV technology and robotics systems, The Team Robotics provides tailored solutions to help businesses optimize their operations and achieve measurable improvements in productivity, safety, and cost-effectiveness. Whether you need unit load AGVs, forklift AGVs, or towing AGVs, The Team Robotics delivers reliable, scalable, and customizable AGV solutions to meet the unique needs of your business.

Reach out to The Team Robotics today to discover how AGVs can transform your warehouse or manufacturing facility, driving success and efficiency in every aspect of your operations.